Tech Frontiers

There was an era when correction of exploded nodules were almost impossible through heat treatment. Carbide can be corrected easily by heat treatment and slow cooling over phase change temperature. Required mechanical properties can be regained in case of some % of carbide in ductile iron. This exercise involves the methodology on how the mechanical properties of exploded nodules can be regained to a large extent.In hypereutectic nodular cast irons, primary precipitation of graphite may lead to graphite flotation in thick section castings. Graphite degeneracy ie. exploded graphite is often associated with this flotation and it appears as precipitates where the nodular form is replaced by star-like or flower-like shape. The exploded graphite develops after the primary spheroidal nodules have reached some tens of microns in diameter. Once nodules explode, properties of the ductile iron deteriorate almost at half of its actual value. Major properties of ductile iron are known for high strength, high ductility, and low hardness with respect to cast iron containing high carbon. This study aims to regain the lost mechanical properties by designing a suitable heat treatment cycle.

What is exploded nodule?

Exploded nodule means deteriorated nodules of the ductile iron from circular to faded. It decreases mechanical property of the ductile iron. Extent of the exploded nodules may be different which will deteriorate mechanical properties of ductile iron accordingly. Exploded nodules generally come for hypereutectic phase (> 4.2% of Ceq)

Reasons for Exploded Nodules

• High carbon equivalent (High carbon, High silicon contain) above hypereutectic point

• High temperature

• High rare earth metal content

Why is Heat Treatment carried out?

Heat treatment of ductile iron is carried out for different purposes, based on mechanical properties and requirements. For stress relieving, cold work treatment is carried out over 510- 675˚C. Normalising 870-940˚C, Hardening 840˚C. Annealing is done generally at 820˚C with a soaking time of 1 hour

In case of derogation of nodule to exploded, mechanical properties also go off. To meet the standard mechanical properties of ductile iron, it needs to be rejected. Correction of mechanical properties generally do not come through Heat Treatment (Annealing) because microstructures cannot be changed much through annealing. Phase transformation occurs only for carbide structures.

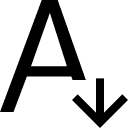

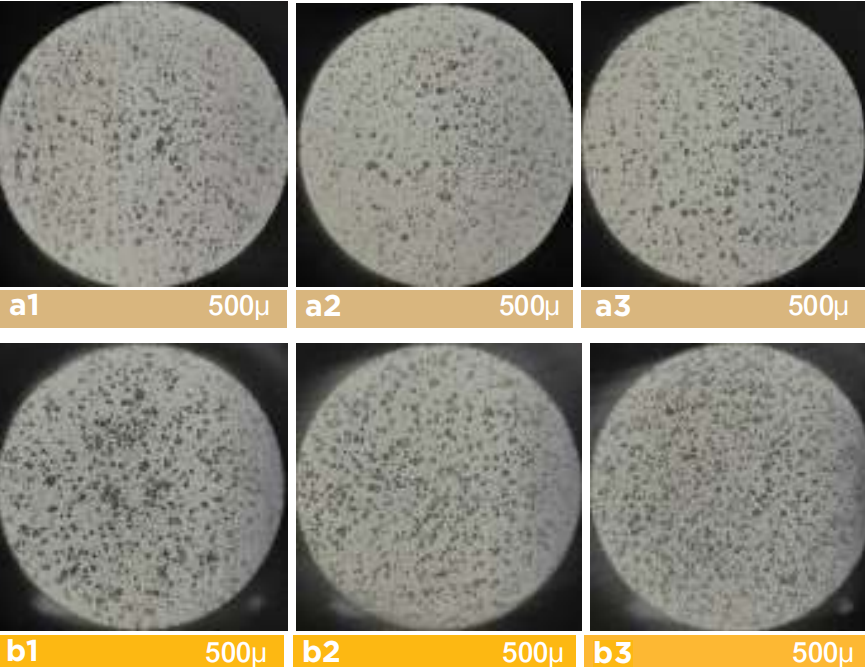

Fig 1:

Microstructures of exploded nodules ductile iron before annealing (a) Unetched and (b) Etched

Table-1:

Mechanical properties of typical exploded nodules before annealing

|

Sample dimensions |

Mechanical properties |

||

|

Gauge length, mm |

Gauge diameter, mm |

UTS, Mpa |

% Elongation |

|

30 |

6.0 |

247 |

2.5 |

|

60 |

12.0 |

312 |

3.4 |

Trials & Experiments

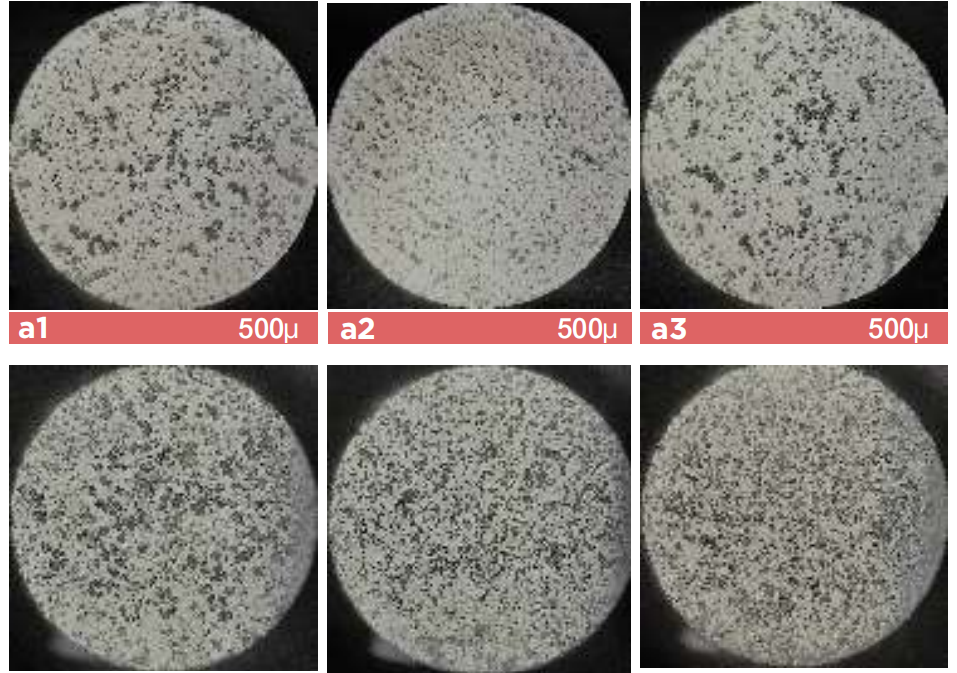

Annealing of deteriorated nodules conducted over the soaking time of 1 hr on 820˚C. Below results favours our assumptions. Heat treatment cycle: Heat treatment of the exploded nodules samples were conducted over soaking temperature of 820˚C for 1 hr. Figures 2(a) & (b) represent the change of temperature with time.

Fig 2(a):

Heat treatment cycle for 820˚C soaking temperature for 1 hr trial

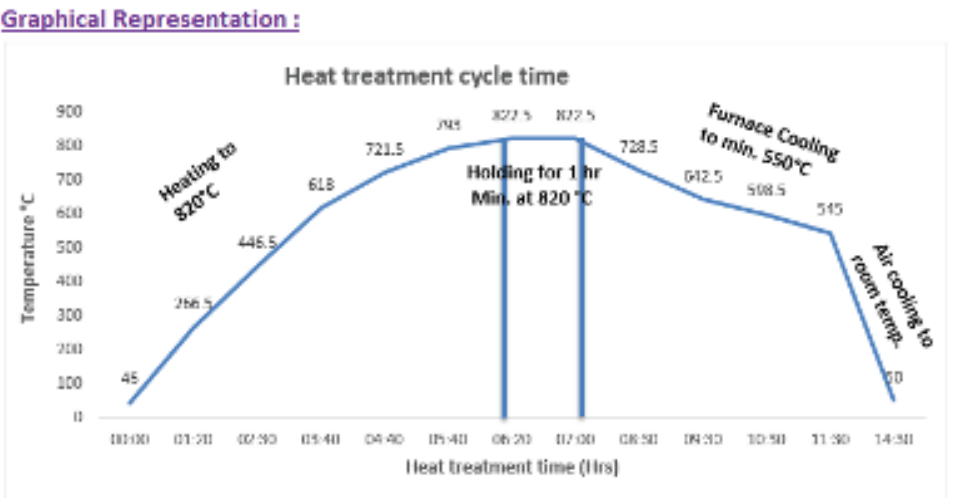

Fig 2(b):

Heat treatment cycle for 920˚C soaking temperature for 1 hr trial

|

Sample dimensions |

Mechanical properties at 820oC HT |

Mechanical properties at 920oC HT |

|||

|

Gauge Length, mm |

Gauge Diameter, mm |

UTS, Mpa |

% Elongation |

UTS, Mpa |

% Elongation |

|

30 |

6.0 |

355 |

6.0 |

432 |

9.0 |

|

|

|

426 |

14.7 |

|

|

|

60 |

12.0 |

278 |

4.0 |

448 |

7.3 |

|

|

|

357 |

5.0 |

473 |

8.5 |

Microstructure of the samples was checked through optical microscope, below are the results after treatment. Most of the samples were not ok. Photograph of one of these is given in Fig 3.

Microstructure

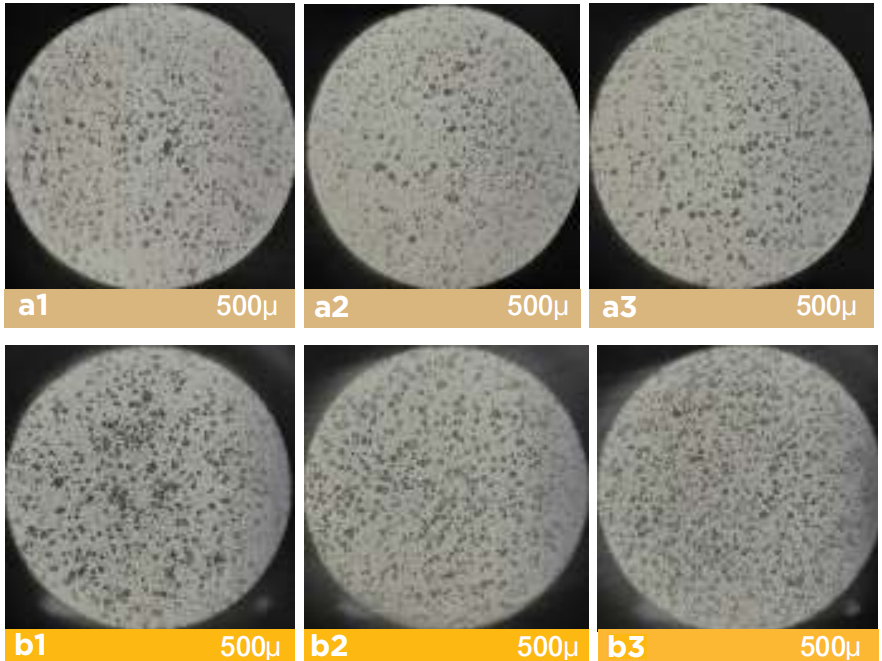

Fig 3:

Microstructures after heat treatment at 820˚C for 1 hr; (a) Unetched and (b) Etched

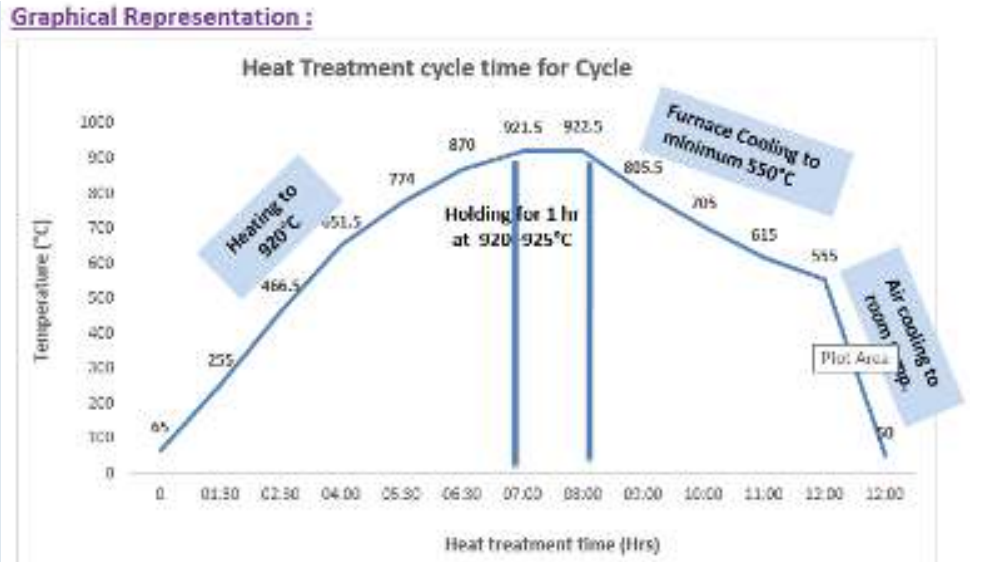

Fig 4:

Microstructures after heat treatment at 920˚C for 1hr;(a) Unetched and (b) Etched

Table-3:

Microstructures of pre and post annealing heat treatment of exploded nodules at 820oC and 920oC

| Specimen No | Item No | Wt/Pcs (in kg) |

Graphite Morphology before and after heat treatment (HT) | ||

|---|---|---|---|---|---|

| Before annealing | H. T. at 820°C | H. T. at 920°C | |||

| 1 | 01H13A | 34.5 | Exploded | Ok | |

| 2 | 05H51C | 64 | Exploded | Exploded | OK |

| 3 | 01H14A | 65.45 | Exploded | Exploded | OK |

| 4 | 06H28B | 130 | Exploded | Exploded | OK |

| 5 | 07H15A | 130 | Exploded | Exploded | OK |

| 6 | 04H30C | 39.24 | Exploded | Exploded | OK |

| 7 | 05H07A | 33 | Exploded | Exploded | OK |

| 8 | 05H23B | 37 | Exploded | Exploded | Exploded |

| 9 | 05H06A | 172 | Exploded | Ok | |

| 10 | 05H09A | 172 | Exploded | Exploded | OK |

| 11 | 04H28B | 172 | Exploded | Exploded | OK |

| 12 | 04H28A | 172 | Exploded | Exploded | OK |

• Annealing of deteriorated nodules conducted over the soaking time of 1 hr on 920oC

• Heat treatment of the same sample of trial No 1 is conducted over the soaking temperature of 920oC under below cycle time (Fig No 2).

• Microstructure of heat-treated samples are below, most of the samples has become ok now (shown in Table-4).

Microstructure

Mechanical properties of heat-treated samples are now ok with respect to minimum requirement of elongation of 5% and tensile strength 420Ma.

Results

90% of the material got ok after 2nd time annealing on 920oC Soaking temperature.

Conclusions

Lost Mechanical properties of exploded ductile iron can be regained to a large extent. Faded level of microstructure of exploded nodules can be reduced to some extent for desired mechanical properties. Required soaking temperature is 920oC and time is 1hr

References

1. Callister’s Material science and engineering.

2. Roxana Ghergu, Lena Magnusson Aberg, Jacques Lacaze, A possible mechanism for the formation of exploaded graphite in nodular cast iron.

3. Sukomal Ghosh, National Metallurgical Laboratory, Jamshedpur, Heat Treatment of Cast Irons.

4. Daniel de Oliveira Fernandes 1,* , Carla TatianaMota Anflor 1 , Jhon Nero Vaz Goulart 1 and Besim Barano˘glu 2. Nodular Cast Iron GGG40, 60, 70 Mechanical Characterization from Bars and Blocks Obtained from Brazilian Foundry.

5. Radosław Winiczenko, Mieczysław Kaczorowski, Andrzej Skibicki, The microstructures, mechanical properties, and temperature distributions in nodular cast iron friction-welded joint.

6. Keivan Amiri Kasvayee’s Microstructure and deformation behaviour of ductile iron under tensile loading.

7. Lab reports.