Oversight

AUSTENITIC SUPER STAINLESS STEEL GRADE CN3MN (UNS J94651)

A REVIEW FOR STEEL FOUNDRIES

INTRODUCTION

Super Austenitic Stainless (SASS) are used widely in extreme environments, such as offshore oil wells, chemical and food processing equipment, paper and pulp industries, specifically bleaching process, and sea water systems, where the high corrosion resistance, toughness is required.

Super Austenitic stainless steels are subgroup of Austenitic stainless steels only but contain higher amounts the regular constituents like chromium (19-38%), nickel (17-38), molybdenum (2-8%) and nitrogen (0.15-0.5%).

As the name indicates, these materials retain the microstructure of Austenite at room temperature, and basically Face Centered Cubic (FCC) crystal structure. The atoms are located at the corners and face centre of fcc of cubic lattice. Cr, Mo, Ni, Mn, and Cu elements occupy the crystal lattice substitution, whereas C, and N2 occupy the interstitial sites.

CN3MN is iron chromium nickel, molybdenum alloy, commonly referred to as 6%Mo. super austenitic. Since present situations in critical applications demand more and more, CN3MN is gaining importance. Only maintaining the chemistry is not important, process control and heat treatment process carry importance. This paper tries to help fellow foundrymen to achieve the expected properties, in sand castings.

OBJECTIVES

The foundries, need, the basic characteristics of the alloys. Melting, deoxidation, selecting right composition, processing, heat treating and upgrading. The attempt is made in this direction.

Keywords

Super austenitic stainless steels, CN3MN, heat treatment, embitterment, welding, corrosion, testing, machining, application, castings.

This alloy is covered in ASTM A351, A744, and A744.

| CASTING MINIMUM MECHANICAL PROPERTIES (AT 20°C, UNLESS OTHERWISE SPECIFIED) | ||||

|---|---|---|---|---|

| Rp0.2 [MPa] |

Rm [MPa] |

A% | Hardness [HB] |

Impact [J] |

| 260 | 550 | 35 | 150–210 | 120 |

Others - (Foundry uses)

- Density: 1340⁰ C.-1360 0C based on chemistry.

- Latent heat=180±5 K J /kg (During solidification and cooling rate, as Niyama rule calculation purposes.)

- Pattern maker shrinkage 2.6%

- As per ASME Section IX, P=45 group No.8.2.

- Basic Microstructure-Austenite, presence of carbides in as-cast

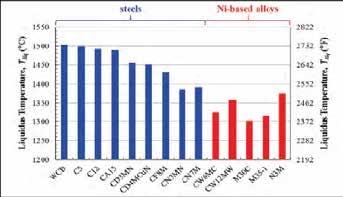

Fig 1: Liquidus temperature

COMPARISONS WITH SIMILAR ALLOYS.

Fig 1: Liquidus temperature

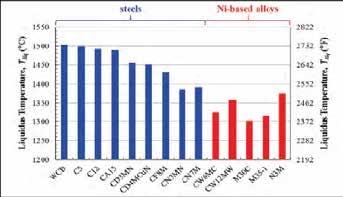

Fig 2: Freezing temperature

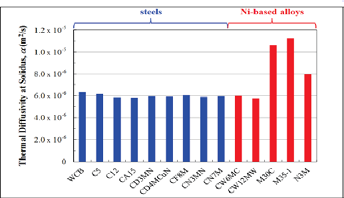

Fig 3: Thermal diffusivity

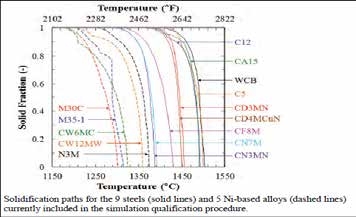

Fig 5: Solidification path

METHODING

Section thicknesses from 5mm and above, can be cast satisfactorily in this alloy. Some thinner sections are feasible depending on casting design and pattern equipment. Sudden changes in section should be avoided. In case, if required a uniform thickness should be maintained as far as possible. This applies to the ascast casting, ie, including finish allowance of 1/8 inch (3 mm) or more on surfaces to be machined. Normally used patternmakers’ shrinkage allowance for this alloy is 5/16 inch per foot.

The patterns carry the key for the dimension control. Wooden patterns may get differences in as-cast dimensions. The quality of patterns also leads to variations. In general, overall dimensions and locations of cored holes can be held to 1/16 inch per foot.

The sand castings mould and cores are usually from nobake processes. Extensive use of zircon or chromite sand is required for heavy junctions, thick portions. In fact, it is preferred that the full cores to be done in chromite sand only. Note that all types of no-bake materials are exothermic in nature, release heat. This additional heat retards, the cooling, and defects are anticipated. The main defects could be, segregations, cracks, etc. This is true for duplex stainless-steel castings where sigma phase carbides are formed, during casting cooling stages only. Chromite sand absorbs the heat, chilling effect is given.

The modulus method is given by R Wlodawer, in his book “Directional Solidification of Steel Casting ‘’. Needs intensive study and calculations and accuracy in prediction is doubtful. For the costly alloys and very limited components, to have the knowledge of characteristics of individual metal properties is needed.

Casting simulation is routinely used in modern foundries because many casting problems can be predicted and eliminated using simulation, rather than through time-consuming and potentially expensive trial-anderror casting process. From the Niyama criterion, a local thermal parameter that is a common output of casting simulation software packages, is regularly used to predict the cooling rate and formations of cavities. An important caveat for casting simulation in general and for the Niyama criterion prediction in particular, is that the results from a simulation are only as good as the casting data that is utilised in the simulation. For a simulation to truly reflect reality it is necessary to have accurate thermo-physical property data for the alloy and mold materials being simulated (in addition to having reasonably accurate boundary and initial conditions), shrinkage porosity defects in steel castings.

Niyama criterion values can be used through casting simulations. It provides enough information, like shrinkage and solidification time. The defects of shrinkage can be verified by NDT testing like radiography. The ASTM standards do give guidance for acceptability

It is necessary to give the necessary data, the pouring time, and temperatures. The temperatures are usual practice to give tapping temperature and the losses in transits and adjustments are predicted.

The foundry practices usually follow common practices of melting of WCB, CF8M etc.where furnace temperature is raised to 1575-16000C. But it is a super heat to CN3MN, in the range of 235-2400C.In this higher range solidification path will change as per the Niyama rules, which is based on thermal criterion.

The solidification shrinkage (For CN3MN, it is β = 2.37%), increases as the alloying element increases.

The rate of metal flow entering the sprue area based on the diameter and pouring time can be calculated. The heat transfer between the mold and the environment and between the top of the riser and the environment are modeled using default settings in the casting simulation software. The heat transfer to the atmosphere is by natural radiation. But the risers contain the hot topping compound which keeps risers hot, and feed in solidification cavities. This effect is also necessary to be considered.

There is a possibility in the variation in porosity and shrinkage pattern, due to the variations in the composition, within the range of the standard specifications. In foundries, costly elements are usually kept at the lower side of the recommended specifications. However, it is note to that, very little effect is expected, and results are insignificant.

HEAT TREATMENT

Molybdenum, Mo is an alloying element, is added to enhance the resistance to improve, crevice and pitting corrosion. Mo with combination of N promotes the selective dissolution of the iron at the surface and leads to enrichment of Cr beneath the passive film. This process adds in increasing the corrosion resistance.

But homogeneity of Mo distribution is not uniform. Mo has a very low solubility in Austenite. There is segregation during casting cooling stage. Dendrites formed during cooling, Mo is getting pushed towards high thermal gradient, liquid zone. This is also called, depletion of Mo. This depletion is also responsible for preferential corrosive attack. The Mo enrichment in the liquid also leads to the formation of brittle interdendritic σ phase that has a deleterious influence on impact toughness. To control, the preliminary heat treatment is given, which is known as the homogenisation, or post-casting heat treatment. It could be the same, given in different standards, apart from main heat treatment.

The exact temperature for the final heat treatment differs. This is a basic solution annealing and quenching in water or rapid cooling by any means. The solution of annealing temperature plays the critical role for the life of the castings. The undisclosed carbides, and presence of segregation (impart the mechanical properties.)

ASTMA 351-1999 states that the castings shall be heated to 11500C, minimum and held for sufficient time to heat the casting to temperature, then quenched in water or cooled rapidly by any means. This is same as ASTMA 743, and A 744 of 1998.(Fig 11)

DIN EN10283-2019 nearest specifications to CN3MN is 1.4588, GX2NiCrMoCuN 25-20-6.

This specification gives the range 1200-12400C, +AT. This means, in between the range solution annealing.

JIP Specification No.33 -2021, MDS116/116S Revision -1, specifies the solution annealing temperature≥12250 C, followed by water/liquid quenching.

Several attempts have been made to establish the heat treatment cycle with temperature and holding times. Later the materials are tested by metallographic methods for the complete dissolution of all carbides.

COMPARISONS WITH SIMILAR ALLOYS.

Fig 6: Dissolutions of sigma carbides

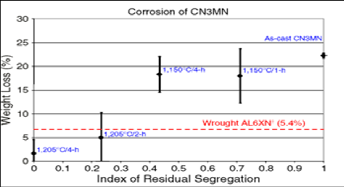

Fig 8: Corrosion weight loss vs Index of segregation.

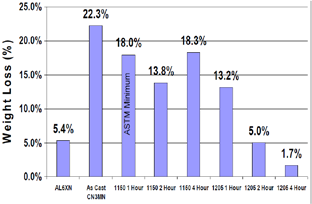

Fig 9(b): Corrosion test results as per ASTM G 48A for CN3MN

(From cast stainless steel technology development-SFSA)

But ASTM A 351-2018 has a temperature of 12000C. And the holding time is 4 hours, given in note B. This cycle is the same as ASTMA 743 and A 744-2020.

DIN EN10283-2019 nearest specifications to CN3MN is 1.4588, GX2NiCrMoCuN 25-20-6.

This specification gives the range 1200-12400C, +AT. This means, in between the range solution annealing.

JIP Specification No.33 -2021, MDS116/116S Revision -1, specifies the solution annealing temperature≥12250 C, followed by water/liquid quenching.

Several attempts have been made to establish the heat treatment cycle with temperature and holding times. Later the materials are tested by metallographic methods for the complete dissolution of all carbides.

DIN EN10283-2019 nearest specifications to CN3MN is 1.4588, GX2NiCrMoCuN 25-20-6.

This specification gives the range 1200-12400C, +AT. This means, in between the range solution annealing.

JIP Specification No.33 -2021, MDS116/116S Revision -1, specifies the solution annealing temperature≥12250 C, followed by water/liquid quenching

Several attempts have been made to establish the heat treatment cycle with temperature and holding times. Later the materials are tested by metallographic methods for the complete dissolution of all carbides.

COMPARISONS WITH SIMILAR ALLOYS.

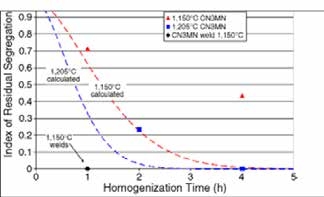

Fig 7: Homogenisation time and temperature with index of segregation

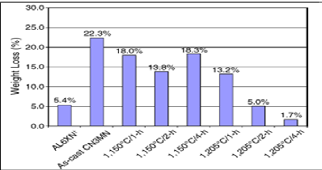

Fig 9(a): Weight loss for different holding time, compared with wrought

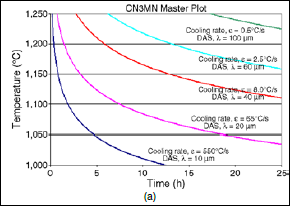

Fig 10: Heat treatment time, temperature and dendrite arm spacing

Figures 6-10 indicate that the optimum cycle could be heating to 12060C and above, holding for minimum 4 hours leads to dissolution of all carbides. The dendritic arm spacing can be achieved up to 35µm in length. This conclusion is reflected in the specification of ASTMA 744 as shown in Table-1.

All castings should be placed in such a way as to ensure free circulation of heating and cooling media around each part during the entire process inclusive of quenching. As a thumb rule, the difference between two castings placement could be the total wall thickness of both castings.

Incorrect heat treatment leads to failure in achieving all properties and becomes prone for defects like embrittlement. This embrittlement leads further to the cracking tendency. This is true for all super austenitic grade castings. The first reason for embrittlement is defined as the precipitates formed at the grain boundaries. The intermetallic precipitates are very brittle. The brittle network is formed on grain boundaries. They deteriorate the mechanical properties; the second mechanism observed in CN3MN is transgranular embrittlement.

Testing

The regular testing are Chemical composition verification and mechanical testing for strength and ductility as per the standard requirements.

As per Norsoke M630-2020 MDS 16/16S following tests need to be done.

Corrosion testing, as per ASTM G48 method A, is required, Testing at 50 oC for 24 hours.

The segregation of elements has no or very little effects in weight loss testing.

No pitting at 20 X magnification, and weight loss should be less than 4.0gm/ M2.

Surface testing, dye penetrate testing, results are accepted as per ASME VIII Division 1, Appendix 7.

The surface hardness should be less than 100HRB, inclusive of parent material, heat- affected zone during welding and welded area, as per NACE 175-2, ISO 15156-2.

The surface soundness of the casting will be confirmed by Liquid Penetrant Inspection as per the practice of ASTM E165.

The radiography is conducted on all critical areas, below the risers, and thick and thin junctions.

The accepted criteria will be as per ASME Section VIII, Division 1; Appendix 7.

The NDT operator should be qualified in accordance with ISO 9712 or its equivalent, certified by 3rd party quality organisations.

Since the castings are nonmagnetic and Austenitic in microstructure, magnetic testing and UT testing are not applicable

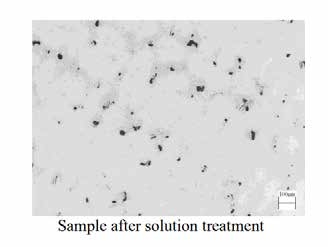

Fig 11: Microstructures of as-cast, and solution heat treated at 12000C for hours, polished and etched, with 60 ml of HCL, 20 ml of HNO3 and 20 ml of acetic acid

WELDING AND UPGRADATIONS

The composition of the deposited weld metal shall be like that of the casting except in grade CN3MN. The alloy, grade CN3MN, needs the composition of the deposited weld metal, similar to that of AWS A5.14 ER NiCrMo-3 or ER NiCrMo-4 or ER NiCrMo-10. Alternatively, the composition of the deposited weld metal shall be similar to that of AWS A5.11 E NiCrMo-3 or E NiCrMo-4 or E NiCrMo-10. This is applicable when post-weld heat treatment is or is not required. The deposit of weld should not contain sulfur (S) and should not exceed 0.015%.

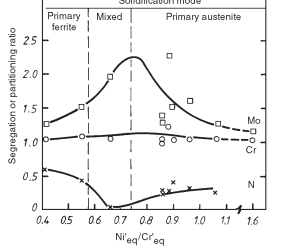

The chloride pitting resistance of high-alloy stainless steel weld metal always is lower than that of nominally matching composition parent metal because of segregation and partitioning of alloying elements Cr and Mo segregated to interdendritic regions. N segregated to dendrite cores.

The segregation of Cr, Mo, and N in fully austenitic deposits decreased as the Ni eq/Cr eq ratio increased.

Ni eq. = Ni + 0.3Mn + 22C + 14.2N + Cu

Cr eq. = Cr + 1.37Mo + 1.53Si + 2Nb + 3Ti

A single-phase austenite structure was predicted when Ni eq /Cr eq > 0.7.

Segregations of elements with Ni eq / Cr eq ratio.

Fig 12: Relation between elemental segregation pertaining to bulk compositions and solidification mode

|

Chemical Composition with reference to ASME BPVC SEC II C-2021 |

|||

|---|---|---|---|

| Elements | ENiCrMo-3 | ENiCrMo-4 | ENiCrMo-10 |

| C | 0.10 | 0.02 | 0.02 |

| Mn | 1.0 | 1.0 | 1.0 |

| Fe | 7.0 | 4.0-7.0 | 2.0-6.0 |

| P | 0.03 | 0.04 | 0.03 |

| S | 0.02 | 0.03 | 0.015 |

| Si | 0.75 | 0.2 | 0.2 |

| Cu | 0.50 | 0.50 | 0.50 |

| Ni | 55.0 min | Rem | Rem |

| Co | 2.5 | 2.5 | |

| Cr | 20.0-23.0 | 14.5-16.5 | 20.0-22.5 |

| Mo | 8.0-10.0 | 15.0-17.0 | 12.5-14.5 |

| V | 0.35 | 0.35 | |

| W | 3.0-4.5 | 2.5-3.5 | |

| Nb plus Ta | 3.15-4.15 | ||

Remarks:

1. All elements are in weight percentage

2. Single digit shows maximum

Over the compositional range when studied, weld metal pitting resistance was dependent mainly on Mo content and segregation. Mo and N enhanced weld metal corrosion resistance in H2SO4.

It is necessary to get a welder qualified as per ASTMA 488 or ISO 11970; or ASME Section IX (As per ASME Section IX, P=45 group no.8.2.) for both major and minor, upgradations. After all major weld repairs and after those minor weld repairs involving either of the following conditions will be followed, (1) welding on a wetting surface, or (2) welding that heats a wetted surface to or above 425 °C, the post weld heat treatment is necessary. It will be the same as the original heat treatment. It involves the dissolution of carbides, developed during welding.

The maximum wetted surface temperature of 800 °F [425 °C] permitted on minor weld repairs without subsequent heat treatment for the austenitic grades is necessary to avoid sensitisation to inter granular corrosion. Minor repairs can be made by using a low heat input (example, 50 000 J/in) welding process or by cooling surfaces. The surrounding area to be welded may be covered with a wet cloth. The main concept would be fast conduction of heat. The surface temperature measurement can be accomplished with temperature-indicating crayon or contact pyrometer.

The post weld heat treatment will follow as per the original heat treatments only. PWHT is mandatory as per Norsoke M630 MDS and JIP-33MDS No.IR116/116S, for all types of welding.

The WPS should be qualified, on the same cast material grade (UNS No. J94651) any changes in the filler material inclusive of the brand names call for requalification, for SMAW and FCAW processes. Radiography Testing (RT) is essential for the confirmations of soundness. Hydrotesting leakages are treated as a major defect, and this is not acceptable. Castings are treated as non-acceptable or rejected. If the castings are meant for sour applications, it will undergo the procedures as per NACE1-75-2 or ISO 15156-2,3

MACHINING

Super Austenitic Steels have their own properties. They have low thermal conductivity, high coefficient of friction, and thermal expansion. During machining of these alloys, there is an increase in temperature, at the interface of tool-part, and it goes on building up with increasing cutting speed. The friction between tools and material also contributes to a rise in temperature. This rise in temperature and low thermal conductivity, the surface temperature leads to the surface hardening effects. Increase in surface hardening further contributed to more friction and tool wear. The hardness may rise to 200-350HV.

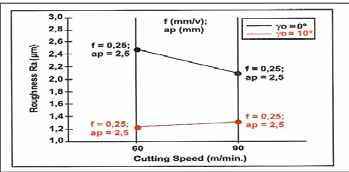

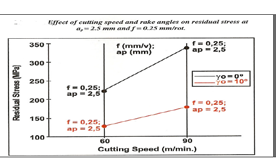

To minimise, above difficulties, it is suggested to use coolants and use triple coating (Ti [C+N] + Al2O3+ Titanium Nitride) tools to reduce work-piece friction. The positive rake angle increases tool life (Figs 13,14).

Table-3: Turning condition

| Influence of turning conditions on the surface properties of CN3MN stainless steel | ||||||||

|---|---|---|---|---|---|---|---|---|

| Turning Conditions | Roughness | Residual | Work hardening | |||||

| Vc (m/min) |

f (mm/v) |

ap (mm) |

γ0 (°) |

Ra (µm) |

Stress (MPa) |

Surface Hardness (HV50gf) |

Thickness of Layer (µm) |

|

| 60 | 0.25 | 2.5 | 10 | 1.22 | 128±15 | 464 | 165 | |

| 90 | 0.25 | 2.5 | 10 | 1.31 | 179±16 | 440 | 215 | |

| 60 | 0.25 | 2.5 | 10 | 2.28 | 223±30 | 471 | 215 | |

| 90 | 0.25 | 2.5 | 10 | 2.10 | 339±41 | 445 | 265 | |

Fig 13: Roughness and cutting speed relation

Table-4: Variables in surface quality

Fig 14: Residual stress vs cutting speed

DEFECTS

The cast products are prone to defects. The common for all could be sand-related: sand fusion, inclusions, melting temperature related cold shuts etc. For these, the process controls are the only solution, like other metal castings. But super austenitic stainless steels like CN3MN are prone for embrittlement, and cracking. This is discussed in the above heat treatment paragraphs. The process, and control in holding temperature, as recommended in Norsok or DIN standards, becomes a criterion to eliminate embrittlement.

APPLICATIONS

The main users of cast parts are based on high corrosive intense applied industries. The common stainless steels fail during the application, and need a long life to survive, the choice becomes to go for super austenitic steels, and CN3MN becomes a choice. The common industries are aerospace, beverage, biopharmaceutical, brewing, brine concentrators, chemical processing, desalination, distillation, flue gas desulfurisation, food processing, heating furnaces, marine, military and naval, nuclear power, oil and gas production, offshore platforms, pharmaceutical, pulp and paper, seawater handling equipment, semi-conductor, steam surface condensers.

Castings - Cryogenic valves and fittings, fittings, flanges, headers, marine fittings, mixing agitators and propellers, pumps, pump sleeves, valves and valve components, milk coolers, rotary strainers, sanitary fittings (dairy), scrubber castings, shaft sleeves, spray nozzles, stuffing boxes, valve bodies and trim.

Corrosives – Acetic acid, antibiotics and drugs, bleaching compounds, formic acid, fruit juices, hot air, hot water, hydrocarbons, hydrochloric acid, organic liquids and acids, nitric acid, organic salts, oxalic acid, phosphoric acid, sea water, sewage, sodium bisulfate, sodium hydroxide, steam, sulfamic acid, 10% sulfuric acid, vinegar, white liquor.

CONCLUSIONS

Super Austenitic Stainless Steels are those exhibits austenite microstructure at room temperature. They contain higher amounts the regular constituents like chromium (19-38%), nickel (17-38), molybdenum (2-8%) and nitrogen (0.15-0.5%).

CN3MN is iron chromium nickel, molybdenum alloy, commonly referred to as %Mo. super austenitic.

The melting process is common to duplex stainless steels. The feeding systems can be followed, as per the simulation.

The heat treatment process, temperature, needs careful considerations, better to follow Norsok, and or JIP-33standards. It should be ≥12050C. ASTM A standards, specify as minimum, whereas DIN standards give the temperature range.

Welding needs the qualifications of the welder. The alloy castings are used for critical applications; post weld heat treatment is necessary for major and minor. It will be the same as the original temperature cycle.

The common defects follow, as per regular casting processes. Embrittlement cracking is an additional factor. It can be taken care of by proper heat treatments only.

ACKNOWLEDGEMENTS

The author thanks all who helped him to prepare this article, his seniors who guided him, and his family members who corrected, and gave shape to present in journal.

References

Standards:

1. ASTM A 351/A 351M – 94a (Reapproved 1999) Standard Specification for Castings, Austenitic, Austenitic-Ferritic (Duplex), for Pressure-Containing Parts.

2. ASTM A351/A351M-18-Standard Specification for castings, Austenitic, Austenitic-Ferritic (Duplex),For Pressure containing Parts.

3. A 743/A 743M – 98ae1, Standard Specification for Castings, Iron-Chromium, Iron-Chromium-Nickel, Corrosion Resistant, for General Application.

4. ASTM A744/A744M-98, Standard Specification for Castings, Iron-Chromium, Iron-Chromium-Nickel, Corrosion Resistant, for General Application.

5. ASTM A744/A744M − 20 Standard Specification for Castings, Iron-Chromium-Nickel, Corrosion Resistant, for Severe Service.

6. ASTMA 744/A744M – 00 Standard Specification for Castings, Iron-Chromium-Nickel, Corrosion Resistant, for Severe Service.

7. DIN EN-10213-2016 English Translation-Steel castings for pressure purposes; English version EN 10213:2007+A1:2016, English translation of DIN EN 10213:2016-10.

8. JIP-33 International Association of Oil and Gas Producers Specification S563-Dec-2021; Material Data Sheets for Piping and Valve Components-MDS No.IR 115 Rev 1.

9. ISO 15156-2 & 3-2020, Fourth edition, Petroleum and natural gas industries — Materials for use in H2S containing environments in oil and gas production.

Others:

10. Sensitivity of Steel Casting Simulation Results to Alloy Property Datasets-Kent D. Carlson and Christophe Beckermann, Proceedings of the 66th SFSA Technical and Operating Conference, paper no.5.3, Steel Founders’ Society of America, Chicago.IL,2012.

11. The Mechanism of Brittle Fracture in CN3MN grade, Super Austenitic Stainless Steel. -Başkan, Mertcan M.S., Department of Metallurgical and Materials Engineering-Master of Science in Metallurgical and Materials Engineering Department, Middle East Technical University February 2015,

12. 1Embrittlement in CN3MN grade Super Austenitic Stainless steels-Mertcan Basken, Scott L Chumbley, and Yunus Earen Kaley-Metallurgical and Material Transactions, Jan 2014.

13. Effect of Composition on Corrosion Resistance of High-Alloy Austenitic Stainless Steel Weld Metals P.I. Marshall and T.G. Gooch-CORROSION–Vol. 49, No. 6-June 1993.

14. Effect of aging heat treatment on the microstructure and impact properties of super austenitic stainless steel ASTM A 744 Gr. CN3MN.

15. Fracture Toughness of Heat-Treated Super austenitic Stainless Steels-C. Muller and L Scott, Chumbley ASM International, JMEPEG (2010) 19:714–720.

16. Influence of Heat Treatment Time and Temperature on the Microstructure and Corrosion Resistance of Cast Super austenitic Stainless Steels J.N. DuPont‡, and J.D. Farren- Article No.055002-1Corrosion May-2011.

17. Steel Castings Handbook Supplement 8 High Alloy Data Sheets Corrosion Series Steel Founders’ Society of America 2004.

18. Optimization of Machining Parameters for Roughing Operation Of ASTM A744 Steel by Marcio Tedeu Gravalos, Marcelo Martin. 10th.Seminar Brasileiro con.papers, 20-22 Sept. 2010.

19. Phase transformation on ASTMA 744 grade CN3MN Super Austenitic Stainless Steel After Heat Treatment- M. Ritoni, M. Martin, F. C. Nascimento and P. R. Mei.